Introduction

Customized 3D printed cell scaffolding is a cutting-edge technology that can revolutionize the field of tissue engineering and regenerative medicine. This technology involves using specialist 3D printing techniques to create customized cell scaffolds. These scaffolds are specifically tailored to meet the unique needs of multiple, specialized cell applications in many diverse industries.

3D printing technology is rapidly advancing, revolutionizing fields like food, engineering, and medicine. One significant breakthrough is the use of 3D-printed scaffolds in drug discovery, clinical research, and regenerative medicine.

For example, customizing microstructure and biochemical cues, researchers can create a better environment for tissue regeneration and cell-scaffold interactions, with ground-breaking potential for medical treatments. Join us as we explore the exciting world of 3D printing technology and its transformative impact on engineering and medicine. In this ultimate guide blog post, we will highlight some examples to showcase 3D scaffolding’s potential for innovative applications.

Breaking the Limitations of Traditional Scaffolds with 3D Printing Technology

Customized 3D-printed cell scaffolding has emerged as a solution to traditional cell culture challenges. Traditional cell scaffolding methods lack control over the microstructure of the scaffold such as pore size and interconnectivity, for example, resulting in poor mechanical strength, a lack of biochemical cues, and surface nano topography for cell-scaffold interactions.

3D cell culture using 3D printed scaffolding however allows cells to grow in an environment that closely mimics their behavior in native tissues, including morphologies, functionalities, and gene expression. This approach has many benefits, including reducing the need for large-scale and expensive animal models, decreasing false positives, and improving clinical research.

Customized 3D printed cell scaffolding provides an ideal platform for reconstructing 3D in-vitro tissue models that temporarily support cells to proliferate, differentiate and deposit extracellular matrix (ECM).

Innovations in Plant-based Food Production with 3D Printing Technology

3D-printed cell scaffolds are revolutionizing the plant-based meat industry. They are being used to create plant-based meat alternatives, with companies such as Redefine Meat, Shandi and SuperMeat leading the way. The scaffolds used in plant-based meat production mimic the structure of meat and allow plant-based cells to grow and form a tissue that is similar to meat, which can then be processed into various products. This technology can reduce our reliance on animal agriculture and address environmental issues such as climate change and deforestation.

For example, to create plant-based products using 3D printed cell scaffolds, researchers create a scaffold that mimics the structure of meat on a microscopic level, and add plant-based cells to the scaffold, which grow and form a tissue that is similar to meat. This tissue can then be processed and shaped into a variety of different products. By reducing the amount of energy required to produce food, this technology offers significant benefits. It is probable that more companies will adopt the use of 3D-printed cell scaffolds for sustainable plant-based food production, as the trend towards plant-based meat consumption continues to grow among health-conscious individuals, vegans, vegetarians, and younger consumers who prioritize food awareness.

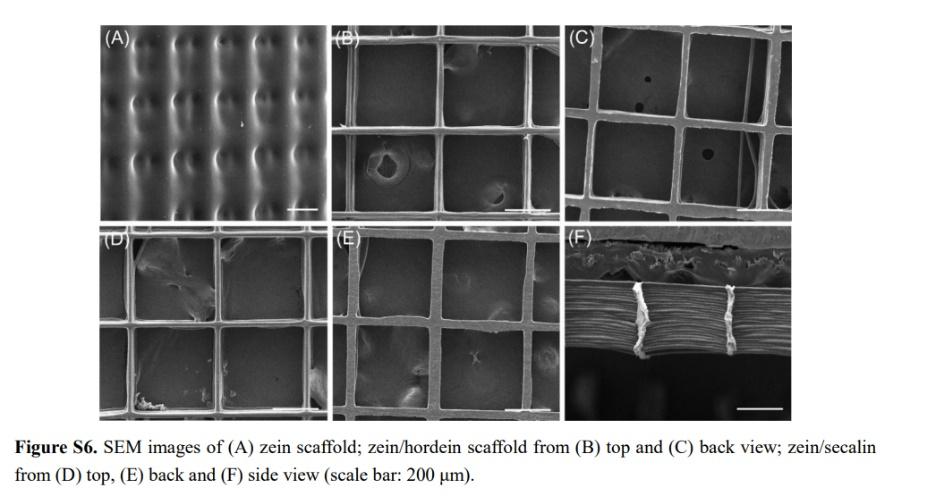

According to research, use of 3D-printed prolamin scaffolds for cell-based meat culture is a promising development in the field of meat alternative production. Prolamin is a protein found in grains such as wheat and corn, making it a cost-effective and widely available material for scaffold production. By providing a structure for cells to grow and develop into meat tissue, 3D-printed prolamin scaffolds offer a more efficient and scalable approach to cell-based meat production, potentially revolutionizing the industry.

KosmodeHealth is a company specializing in 3D cell scaffold printing for plant-based meat production and other applications.

Contact us today to find out how our customizable 3D scaffolds can be adapted for your requirements.

From Lab to Plate: Sustainable Meat Production Using 3D Printing

The traditional meat industry has a significant impact on the environment, from greenhouse gas emissions to deforestation and water pollution. It is well-established that this industry is too unsustainable and resource-intensive in terms of feed, water, land, and methane production.

Lab-grown meat is a sustainable and ethical alternative which uses significantly fewer resources and emitting fewer greenhouse gases. Growing meat in a lab also eliminates the need for antibiotics and hormones, which are used in conventional animal farming.

As the demand for meat alternatives continues to grow, 3D cell scaffolds offer an innovative solution to creating lab-grown meat. By providing a framework for cells to grow in a way that mimics the natural structure of meat tissue, the scaffold promotes the growth and differentiation of muscle cells. This helps researchers optimize the production process and reduce costs.

The use of 3D cell scaffolds allows for the creation of meat products that resemble conventional meat in terms of texture, taste, and nutrition without the need for animal cruelty and slaughter. Better food safety standards can also be built into the production process. From filet mignon to pork cutlets, customized meat production can become a reality.

Photo credit: KosmodeHealth- culture of pork meat tissue

Revolutionizing Healthcare: The Power of 3D Printing Technology in Medicine and Biomedical Research

The field of regenerative medicine has seen a great deal of innovation in recent years, with 3D cell scaffold technology offering new possibilities for tissue engineering and organ regeneration. This cutting-edge technology allows for the creation of customized scaffolds that can be used to support the growth and regeneration of damaged tissues among many other applications.

3D cell scaffolds enable researchers to create complex structures with precise control over porosity, pore size, and other parameters that influence cell behavior. These scaffolds can be made from a variety of materials and can be designed to mimic the natural extracellular matrix of specific tissues. By providing a template for cells to grow and differentiate, 3D cell scaffolds have the potential to revolutionize the way we approach tissue engineering and regenerative medicine, allowing for the creation of functional tissues and organs:

- Artificial organ generation: 3D-printed cell scaffolds can be used in the invitro development of artificial organ models such as skin and used to create functional organs that can be transplanted into patients.

- Medical devices: application of implantable medical devices for tissue repair and regeneration.

- Stem cell research: inducement of stem cell growth and differentiation

- Drug discovery: building invitro 3D tumour models for drug screening purposes, and cellular behaviour studies by co-culturing various cells.

- Cancer research: 3D printed cell scaffolds can be harnessed to study the behaviour of cancer cells in a more realistic 3D environment, which can help researchers better understand the disease and develop new treatments.

- Cancer treatment: By co-culturing various cells within 3D cell scaffolds, researchers can create a more realistic representation of the cellular environment of cancer cells in the body. This enables them to study how different types of cells interact with one another, how drugs affect these interactions, and how cancer cells respond to various treatments.

- Drug testing: 3D-printed cell scaffolds can be used to test the efficacy and safety of new drugs in a controlled laboratory environment.

- Drug delivery: Drug-loaded scaffolds can successfully deliver medicines and provide controlled release. This has the potential to improve treatment outcomes and reduce the risk of side effects, making it an exciting area of research in the field of medicinal chemistry.

- Personalized medicine: 3D-printed cell scaffolds can be customized to match a patient’s specific anatomy, which could be useful for creating personalized medical implants or prosthetics.

- Biotechnology: 3D printed cell scaffolds make the creation of artificial tissue for use in biotechnology research and development possible.

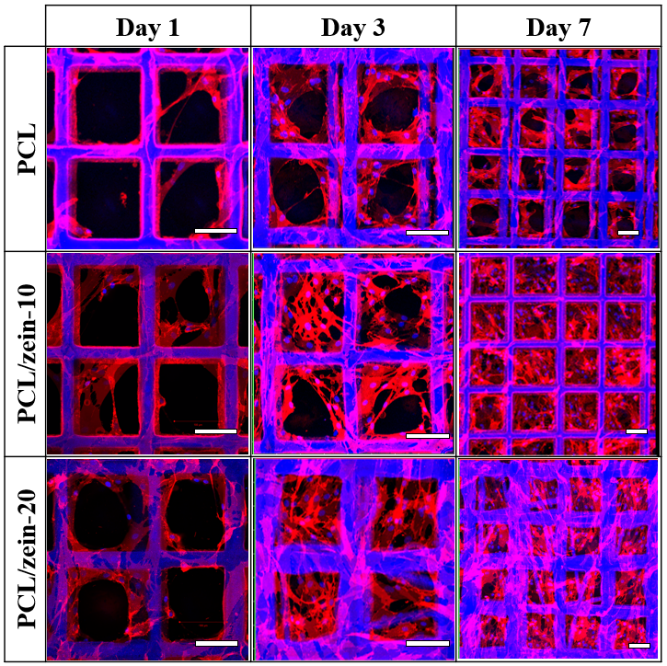

Contact KosmodeHealth to find out more about our specialization in the PCL & PCL/Zein scaffold, its applications, and our 3D scaffold customization services.

Photo credit: KosmodeHealth

Other applications of 3D Scaffolds in Biomedical Science

Biomedical science has made significant advances in developing new technologies that aid the treatment of various medical conditions. 3D printing of cell scaffolds allows for the creation of complex structures that mimic natural tissues and organs. The applications of these 3D scaffolds in biomedical science are varied. Here are just some of the possibilities:

- Wound healing: 3D-printed cell scaffolds are a promising tool for creating customized skin grafts and other materials to help speed up the healing process for wounds and burns.

- Dental implants: Biomedical scientists are exploring the use of 3D-printed cell scaffolds to produce unique dental implants that fit perfectly in the patient’s mouth.

- Bone regeneration: The use of 3D-printed cell scaffolds has the potential for promoting bone growth and regeneration, offering hope for patients with bone injuries or osteoporosis.

- Cartilage repair: 3D printed cell scaffolds can be used to repair damaged cartilage, which is a promising treatment option for individuals with arthritis and other joint-related conditions.

- Nerve repair: biomedical scientists aim to repair damaged nerves using 3D-printed cell scaffolds, which could improve outcomes for patients with spinal cord injuries and other nerve-related conditions.

- Blood vessels: Biomedical scientists are investigating the potential of 3D printed cell scaffolds in creating artificial blood vessels, which could benefit patients with vascular diseases.

- Transplant rejection: 3D-printed cell scaffolds offer a promising solution to minimize transplant rejection by creating transplantable tissues that are less likely to be rejected by the patient’s immune system.

- Heart tissue engineering: 3D printed cell scaffolds can be used to create functional heart tissue, which may offer hope for patients with heart disease.

- Lung tissue engineering: The development of artificial lungs using 3D-printed cell scaffolds is a promising avenue for treating lung diseases.

- Brain tissue engineering: Biomedical scientists are using 3D-printed cell scaffolds to create artificial brain tissue, which may provide insights into the workings of the brain and the development of treatments for neurological conditions.

Contact KosmodeHealth to learn how our revolutionary PPC™ 3D printed Scaffold can be applied to your processes.

The Synergy Between Personalized Medical Treatment and 3D Printed Scaffolding Technology

The potential of 3D cell scaffolds transcends traditional medical science and provide the possibility to enable personalized medicine. By using a patient’s genetic markers to create a customized scaffold, 3D cell scaffolds can provide tailored drug delivery systems that are tailored to each patient. This precision approach to treatment will improve patient outcomes and create more effective and targeted drug treatments.

Personalized implants can also be created using 3D-printed scaffolds, resulting in better outcomes and fewer complications. The combination of personalized medical treatment and 3D-printed scaffolding technology can revolutionize medicine. The main benefits are a more precise and targeted approach to treatment, ultimately leading to a higher quality of life for patients. The article Advanced 3D Printing in Medicinal Chemistry and Drug Delivery describes how 3D printed scaffolds act as a framework for the medicine, allowing for precise delivery to the targeted area, and highlights the advantages of using 3D printing technology to create these structures.

Conclusion

3D-printed cell scaffolds are providing potential in numerous fields, including plant-based meat production, meat culture, and biomedical science. The possibilities have no boundaries: from plant-based meat production, where scaffolds are used to create meat substitutes that taste and feel like real meat, to the biomedical field, where scaffolds show promise in regenerative medicine for repairing damaged tissues and creating artificial organs. 3D scaffolds can be tailored to create personalized implants and drug delivery systems, which lead to better patient outcomes. The potential of 3D cell scaffolds is vast, with endless options for improving human health and the environment. By harnessing the power of 3D cell scaffolds, we can create sustainable food sources, reduce our reliance on animal farming, and transform medical treatments, resulting in a higher quality of health.

Contact KosmodeHealth to learn more about our precise, 3D scaffold customized printing services.

References and Further Reading

Buznyk, O., Greedy, B., Zekonyte, U., Kundu, B., & Mashayekhi, K. (2020). Three-Dimensional (3D) Printed Scaffolds for Bone Tissue Engineering: A Review of the Trends and Designs. Proceedings of the Institution of Mechanical Engineers, Part H: Journal of Engineering in Medicine, 234(8), 835-858. https://www.frontiersin.org/articles/10.3389/fbioe.2020.00287/full

Chen, Y., Zhou, P., Liu, Q., Yan, J., Zhang, R., & Wang, X. (2019). 3D printing of porous titanium scaffolds with controlled internal architecture by PBF and SLM methods. Materials Science and Engineering: C, 104, 109908. https://doi.org/10.1016/j.msec.2019.109908

Gaetani, R., Feyen, D. A., Verhage, V., Slaats, R., Messina, E., Christman, K. L., … & Giacomello, A. (2015). Epicardial application of cardiac progenitor cells in a 3D-printed gelatin/hyaluronic acid patch preserves cardiac function after myocardial infarction. Biomaterials, 61, 339-348. https://doi.org/10.1016/j.biomaterials.201

Gbureck, U., Hölzel, T., Doillon, C. J., Müller, F. A., Barralet, J. E., & Grover, L. M. (2015). 3D printing of bone substitute implants using calcium phosphate and bioactive glasses. Journal of the European Ceramic Society, 35(5), 1845-1852. https://doi.org/10.1016/j.jeurceramsoc.2015.01.004

Kim, B. S., Kwon, Y. W., Kong, J. S., Park, G. T., Gao, G., Han, W., & Kim, M. B. (2020). 3D cell printing of in vitro stabilized skin model and in vivo pre-vascularized skin patch using tissue-specific extracellular matrix bioink: A step towards advanced skin tissue engineering. Biomaterials, 235, 119794. https://doi.org/10.1016/j.biomaterials.2020.119794

Lee, J. M., Sing, S. L., Yeong, W. Y., & Wiria, F. E. (2019). 3D bioprinting in cardiovascular tissue engineering: A review. Journal of Medical and Biological Engineering, 39(2), 159-168. https://doi.org/10.1007/s40846-019-00456-2

Luo, L., & Shoichet, M. S. (2004). A photolabile hydrogel for guided three-dimensional cell growth and migration. Nature Materials, 3(4), 249-253. https://doi.org/10.1038/nmat1092

Scotti, C., Tonnarelli, B., Papadimitropoulos, A., Scherberich, A., Schaeren, S., & Schauerte, A. (2013). Recapitulation of endochondral bone formation using human adult mesenchymal stem cells as a paradigm for developmental engineering. Proceedings of the National Academy of Sciences, 110(7), 2.637-2.642. https://doi.org/10.1073/pnas.1220108110

Tocchio, A., Tamplenizza, M., Martello, F., Gerges, I., Rossi, E., Argentiere, S., … & Milani, P. (2020). 3D printing and electrospinning of composite hydrogels for novel tissue engineering scaffolds. Biofabrication, 12(4), 042001. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7793358/

Wang, H., Xu, Y., Zhang, Q., Jin, H., & Jiang, G. (2019). 3D printing: An emerging technology for the fabrication of vascular constructs for organ regeneration. Biotechnology Letters, 41(7-8), 959-968. https://doi.org/10.1007/s10529-019-02690-6

Zhou, Y., Chen, Y., Zhang, H., Chang, X., Liu, C., Ma, P. X., & Guo, B. (2020). 3D bioprinting of collagen-based scaffolds for tissue engineering and regenerative medicine. Annals of biomedical engineering, 48(2), 579-594. https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7312878/